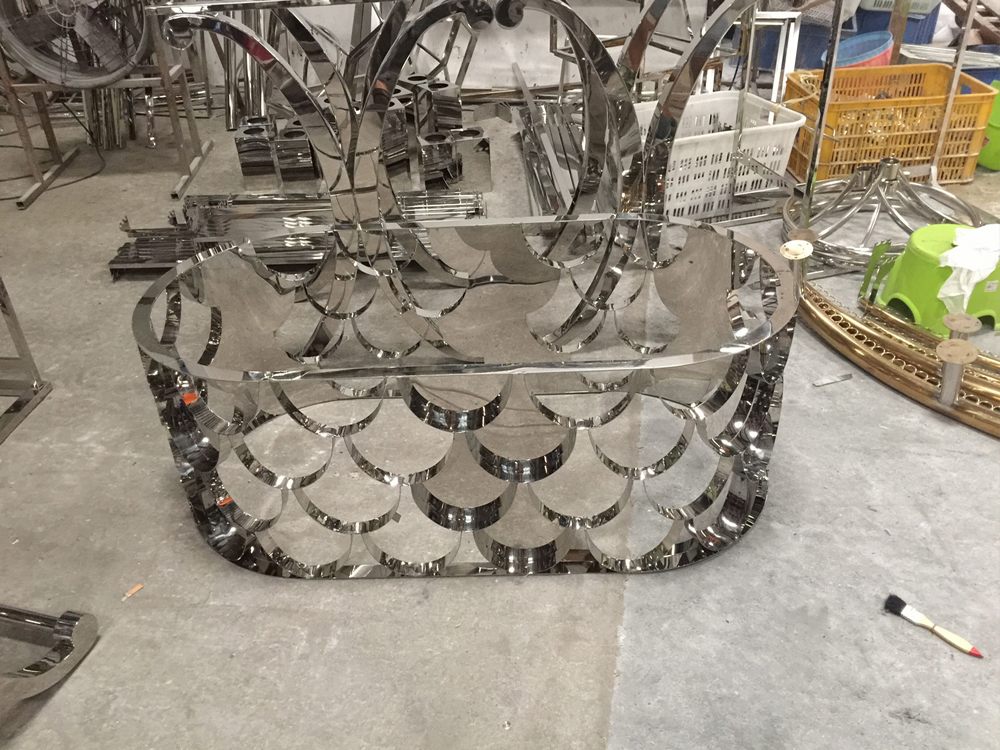

Creating large-scale metal sculptures requires a delicate balance between artistic vision and engineering precision. Artists employ several key techniques to ensure structural integrity, beginning with meticulous material selection. High-quality metals like stainless steel, bronze, or corten steel are chosen for their durability and resistance to environmental factors.

The design phase incorporates engineering principles, often using computer-aided modeling to simulate stress points and load distribution. Internal frameworks, such as steel armatures or reinforced skeletons, provide hidden support while maintaining the sculpture’s aesthetic form.

Fabrication techniques like welding, bolting, and riveting are carefully executed to withstand wind, seismic activity, and thermal expansion. Many artists collaborate with structural engineers to test prototypes and refine stability.

Finally, protective coatings and regular maintenance safeguard against corrosion, ensuring these monumental artworks endure for generations. By merging art with science, sculptors transform metal into enduring masterpieces.